Get a Quote from Chinese Towel Factory: The 2026 Ultimate Bulk Sourcing Guide

Is your procurement process stalled by vague, slow, or overpriced quotations? For warehouse managers and procurement officers, the gap between a project's budget and the final landed cost often stems from a single failure point: the initial Request for Quotation (RFQ). If you ask a generic question, you get a generic—and usually expensive—answer.

To secure competitive pricing for OEM programs, you must speak the language of the production floor. This guide dissects exactly how to get a quote from a Chinese towel factory that is accurate, transparent, and optimized for your specific supply chain needs. We will move beyond basic price lists to understand cost drivers, technical specs, and negotiation leverage.

Ready to Transform Your Procurement Process?

Get a professional quote that matches your exact specifications

Request Your Custom Quote Now1. The Anatomy of a Perfect Towel RFQ

Most buyers send an email saying, "I need hotel towels, please quote." This is a critical error. To a manufacturer, this signals a lack of technical knowledge, often resulting in a high "risk buffer" added to the price. To get a precision quote, you must build a comprehensive Tech Pack.

A professional RFQ must include the EAV (Entity-Attribute-Value) parameters. Without these, the factory cannot calculate raw material usage (cotton consumption) or loom time.

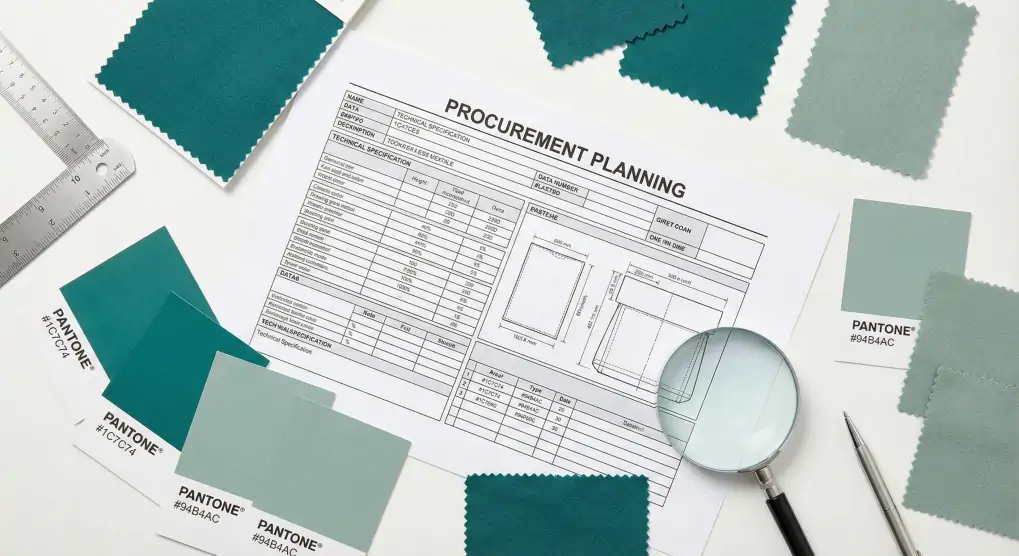

Professional technical specification sheet with fabric swatches and Pantone color chips for precise towel manufacturing RFQ

2. Deciphering Material Costs: Cotton Grades and Yarn Counts

The raw material accounts for 50-60% of the FOB price. When you request a quote, specifying "100% Cotton" is insufficient. The specific yarn count determines both the price and the durability of the towel.

Cotton Yarn Specifications

- 16s/1 (Single Loop): Uses lower grade, shorter staple cotton. It is cheaper and fluffs up quickly but has lower durability.

- 21s/2 (Double Loop): The industry standard for institutional and hotel use. Two strands are twisted together, providing high tensile strength and resistance to industrial laundering.

- 32s/2 (Premium): Uses long-staple cotton for a smoother, luxury finish.

Ask your supplier to quote 21s/2 and 32s/2 separately. This allows you to evaluate the cost-benefit ratio of upgrading your product quality.

3. The Impact of GSM (Weight) on Pricing

GSM (Grams per Square Meter) is the density of the towel. A heavier towel consumes more cotton, directly increasing the unit price. However, there is a production nuance: machine efficiency.

Extremely heavy towels (above 650 GSM) run slower on the loom, increasing labor costs. Extremely light towels (below 300 GSM) are prone to breakage, causing downtime. The "sweet spot" for pricing efficiency is usually between 400 GSM and 550 GSM. Ensure your quote request specifies a weight tolerance (e.g., ±5%).

Close-up macro shot of cotton towel loops being weighed on digital scale for precise GSM verification

4. Understanding MOQ (Minimum Order Quantity) and Vat Sizes

Why does the price drop significantly at 1,500kg? It comes down to the dyeing vat.

Dyeing vessels have fixed capacities (e.g., 500kg, 1,000kg, 2,000kg). If you order a custom color that requires 300kg of fabric but the factory only has a 500kg vat, they must still fill the vat with water and chemicals. You pay for the wasted capacity.

Ask the factory, "What is the optimal batch size for your dyeing vats?" Adjusting your order quantity to match their machine capacity can lower your unit cost by up to 15%.

5. Customization Techniques: Jacquard vs. Embroidery vs. Printing

Your branding method heavily influences the setup fees and unit costs in the quote.

Branding Methods Comparison

- Jacquard Weaving: The logo is woven into the structure of the towel. High initial setup cost (CAD design and beam preparation) but zero extra unit cost. Best for high-volume orders.

- Embroidery: Charged by the stitch count (e.g., per 1,000 stitches). Ideal for smaller logos on luxury items.

- Reactive Printing: Offers unlimited colors but requires expensive screen charges per color.

Industrial embroidery machine in action, stitching custom logo on towel with precision and speed

6. The "Hidden" Costs: Packaging and Labeling

A standard quote usually assumes "bulk packing" (e.g., 10 pieces per polybag, compressed). If your distribution center requires specific retail packaging, you must define it upfront.

Adding a header card, individual zipper bag, or barcode sticker involves manual labor. In China, labor costs are rising. "Special Packing" can add $0.20 to $0.50 per unit. Always specify:

- Wash Label: Material (Satin vs. Tyvek) and language requirements.

- Hang Tags: Thickness of paper and drilling hole requirement.

- Carton Markings: Essential for efficient warehousing intake.

7. Compliance and Testing Costs (Oeko-Tex & REACH)

For buyers in the EU and North America, chemical compliance is non-negotiable. A cheap quote often relies on Azo-based dyes which are banned in many jurisdictions.

When getting a quote, explicitly require Oeko-Tex Standard 100 compliance. Legitimate factories will include the cost of compliant, eco-friendly dyes. If a competitor's quote is 20% lower, they are likely cutting corners on chemical safety, putting your company at legal risk.

Scientist in laboratory testing towel fabric samples for chemical safety and Oeko-Tex compliance certification

8. Analyzing Lead Times and Production Schedules

Price is irrelevant if the stock arrives after your peak season. A comprehensive quote must include a production timeline.

Production Timeline Breakdown

- Lab Dip (Color Match): 5-7 Days.

- Pre-production Sample: 10-14 Days.

- Mass Production: 30-45 Days (depending on loom availability).

Be wary of factories promising "20-day delivery" for custom orders; this usually indicates they are outsourcing to a smaller, less regulated workshop.

Get Production Timeline9. Shipping Terms: FOB vs. EXW vs. DDP

The Incoterm you choose drastically changes the final number on the spreadsheet.

Shipping Terms Explained

- EXW (Ex Works): You handle everything from the factory door.

- FOB (Free on Board): The factory pays to get goods to the port (e.g., Tianjin or Shanghai). This is the B2B standard.

- DDP (Delivered Duty Paid): The factory handles shipping, customs, and duties. This is the easiest but often includes a 10-15% premium for the service.

Ensure you are comparing apples to apples. A DDP quote will always look higher than an FOB quote but may be cheaper in the long run.

Compare Shipping Options10. Technical EAV Parameter Table

Use this table structure when sending your inquiry to ensure no data is missing.

| Entity | Attribute | Value Requirement (Example) |

|---|---|---|

| Product | Construction | 100% Cotton, 16s/1 Pile, 16s/1 Weft |

| Physical | Size & Weight | 70x140cm, 500 GSM (±15g) |

| Visual | Color | Pantone 19-4052 Classic Blue |

| Finish | Hemming | Double stitched, 2cm border |

| Packing | Carton Spec | 5-ply corrugated, Max 15kg/carton |

11. Payment Terms and Financial Security

Standard industry terms for OEM production are 50-30% Deposit / 50-70% Balance. The balance should be paid after a successful Third-Party Inspection (TPI) but before shipment.

Accept 100% upfront payment for a small account below USD 5000. If a quote demands this, it is a red flag. For orders exceeding $50,000, ask if the factory accepts a Letter of Credit (LC), which provides security for both parties.

Business handshake between procurement manager and factory owner after successful contract negotiation

12. Validating the Quote: The "Sample First" Rule

A quote is just a promise; a sample is the proof. Before signing a purchase order based on a price, purchase a custom sample.

While sample fees may seem high ($50-$800), they cover the cost of pausing a loom to run a MOQ fabrics. Expert Tip: Ask the factory to refund the sample fee against the bulk order. Most reputable manufacturers will agree to this in the quotation phase.

Request Custom SampleReady to Secure Your Supply Chain?

Don't settle for estimates. Get a binding, factory-direct quotation that meets your exact technical specifications.

Request Your Custom Quote NowOur engineering team is ready to analyze your Tech Pack and provide a detailed cost breakdown within 24 hours.