The Ultimate China Towel Manufacturer Factory Audit Checklist (2025)

In the global textile market, sourcing from China offers immense advantages in scale and cost. However, navigating the landscape of suppliers requires rigorous due diligence. While online communication and sample evaluations are useful, they cannot replace the insights gained from a physical factory visit. An on-site audit is the most critical step to verify a manufacturer's claims and ensure their operations align with your quality, ethical, and production standards.

Relying on subjective impressions during a factory tour is a recipe for risk. A systematic, comprehensive checklist removes guesswork, ensuring every crucial aspect of the operation is inspected and evaluated objectively. This guide provides a detailed checklist specifically designed for auditing towel manufacturers in China, applicable to suppliers of bath towels, hand towels, OEM custom towels, and large-scale hotel linen programs.

Why a Factory Audit is Non-Negotiable for Towel Sourcing

A factory audit is not merely a formality; it's a foundational element of a successful B2B sourcing strategy. It provides the empirical data needed to move forward with a supplier relationship confidently.

Verifying Production Capability and Expertise

An audit allows you to witness the factory's operations firsthand. You can assess the condition of their machinery, the organization of their production lines, and the expertise of their staff. This physical verification confirms whether the factory can handle your volume requirements (MOQ and bulk orders) and technical specifications for specialized products like jacquard or embroidered towels.

Ensuring Consistent Quality Control at the Source

Quality is paramount. An on-site inspection reveals the supplier's commitment to quality control (QC). You can observe their processes for inspecting incoming raw materials (like cotton yarn), in-process checks on the weaving and dyeing lines, and final product inspections. This insight is far more valuable than a single perfect sample, as it indicates their ability to maintain quality across a full production run.

Request a Quote for Your Custom TowelsAssessing Social and Ethical Compliance (Crucial for Brand Reputation)

In today's market, brand reputation is intrinsically linked to ethical sourcing. An audit is your chance to assess working conditions, safety standards, and labor practices. Verifying compliance with standards like BSCI (Business Social Compliance Initiative) or SA8000 protects your brand from the significant risks associated with unethical supply chains.

Mitigating Risks and Building Transparent Long-Term Partnerships

The audit process builds a foundation of transparency. By openly discussing your findings with factory management, you establish a professional relationship based on mutual understanding. This initial dialogue helps mitigate future risks related to production delays, quality fade, or communication breakdowns, paving the way for a stable, long-term partnership.

Pre-Audit Preparation: What to Do Before You Go

A successful audit begins long before you set foot in the factory. Thorough preparation ensures your visit is efficient, targeted, and yields the information you need.

Document Review Request

Request the following documents from the factory well in advance of your visit. Their willingness and speed in providing these is an early indicator of their transparency and organization.

- Business Licenses: Business License, Tax Registration, and Export License to verify their legal status.

- Quality System Certificates: ISO 9001 certification indicates a structured quality management system.

- Social & Environmental Certificates: Look for OEKO-TEX (for harmful substances), BSCI (social compliance), or GOTS (for organic textiles) if relevant to your brand's requirements.

Schedule and Agenda Confirmation

Do not show up unannounced. Work with your factory contact to establish a clear schedule. A typical one-day audit agenda should include a management meeting, a full factory tour (from raw materials to packing), a review of QC records, and a closing meeting to discuss findings.

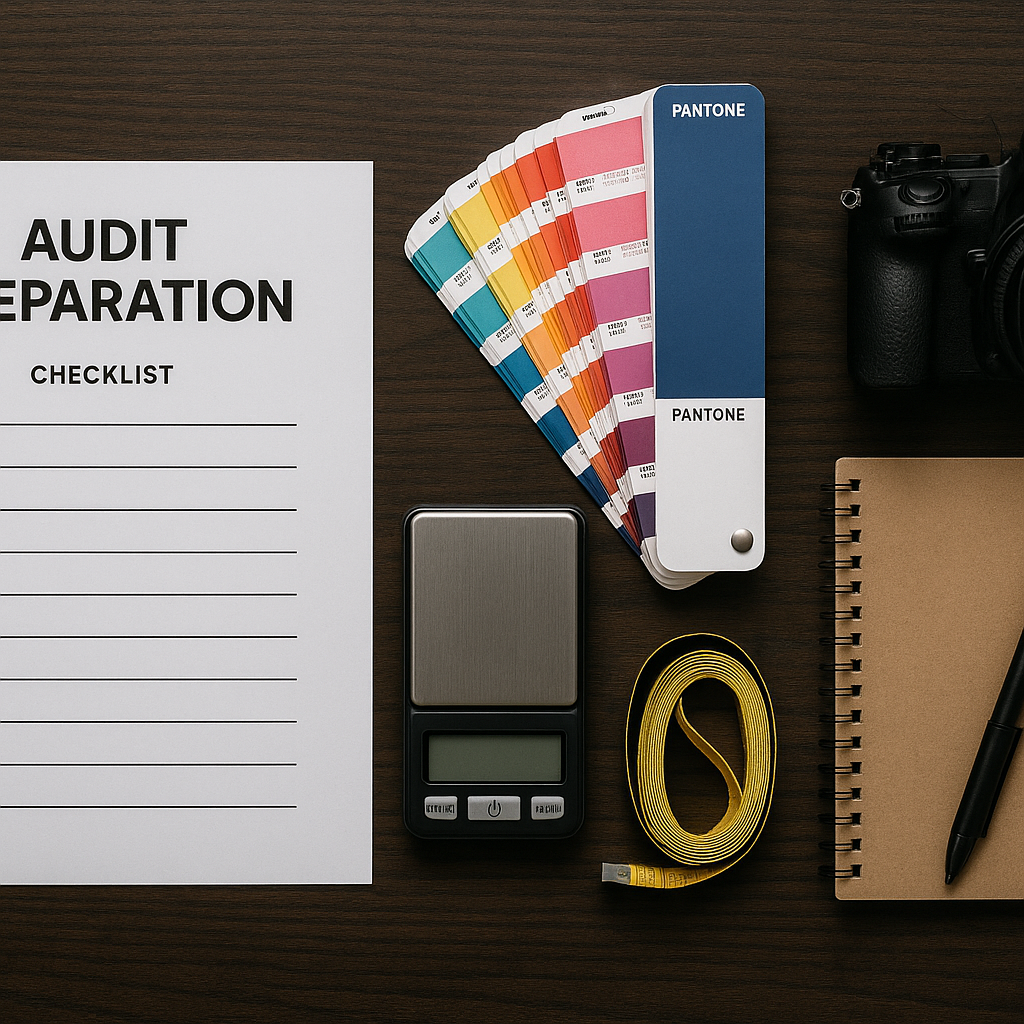

Prepare Your Audit Kit

Arrive prepared with the right tools to conduct a professional assessment. Your kit should include a notebook, a high-resolution camera, a digital GSM (grams per square meter) scale, Pantone color swatches for color checking, a measuring tape, and a printed copy of your audit checklist.

The Comprehensive Factory Audit Checklist

Use this structured checklist to guide your inspection, ensuring no critical area is overlooked.

1. Company Profile and Management Assessment

Understand the business you're partnering with. Inquire about the factory's founding year, primary export markets, and total number of employees. Assess the management team's structure—is there a clear hierarchy? Is communication with their team, especially the foreign trade department, smooth and professional? Confirm they have dedicated departments for quality control and international sales.

2. Production Capability and Equipment Inspection

Walk the entire production floor. The process should logically flow from the yarn warehouse through dyeing, weaving, finishing (bleaching, softening, dewatering), cutting, sewing, and any value-add processes like embroidery or printing, all the way to the final packing area. Pay close attention to key equipment like looms, dyeing machines, and dryers. Note their brand, model, and general condition—are they modern and well-maintained or outdated and in disrepair? Finally, assess their production capacity by asking for their monthly/annual output and current production load.

3. Quality Control System and Testing Audit

A robust QC system is non-negotiable. Evaluate the QC team's size and structure. Do they perform incoming quality control (IQC) on raw materials like yarn? Are there in-process quality control (IPQC) checks at critical stages? Is there a final quality control (FQC) inspection before goods are packed? Ask to see their internal laboratory. What tests do they perform (e.g., GSM weight, colorfastness, water absorbency, pH value, tensile strength)? Do they periodically send products to third-party labs for validation? Crucially, understand their process for identifying, documenting, and handling defective products.

4. Social Compliance and Working Conditions

Observe the general environment. Are the workshops clean, well-lit, and properly ventilated? Inquire about employee welfare, asking to see (if appropriate and possible) timekeeping records and payroll examples to verify working hours and fair wages. The factory must have a strict policy against child labor and forced labor. Look for essential health and safety measures: clearly marked fire exits, functional fire extinguishers, safety guards on machinery, proper management of chemicals, and accessible first-aid stations.

5. Sample Room and R&D Capability

The sample room is a window into the factory's capabilities and creativity. It should be well-organized, clean, and showcase a wide range of products. Evaluate the quality, design, and finishing of the existing samples. This is also the place to discuss their R&D capabilities. How quickly can they produce a new custom sample? How do they approach new product development for their OEM program clients?

6. Supply Chain and Raw Material Management

A towel is only as good as the cotton it's made from. Ask about their primary raw material suppliers. Are they sourcing reliable cotton from well-known regions like Xinjiang, or importing it from India or Pakistan? Examine their raw material inventory management process—is the warehouse clean and dry to prevent mildew? Inquire about their traceability system. Can they trace a finished product batch back to the specific lot of cotton yarn used?

Post-Audit: Evaluation and Follow-Up Actions

The work isn't over when you leave the factory. The follow-up phase is where you translate your observations into an actionable decision.

Compiling the Audit Report

Immediately after the visit, compile your findings into a formal report. Use a scoring system (e.g., Excellent, Good, Acceptable, Unacceptable) for each checklist item to create an objective summary. Attach photos from your visit as visual evidence to support your ratings.

Key Decision-Making Factors

Summarize the factory's core strengths and potential risks. Is their strength in high-volume production, or in high-quality, complex OEM projects? Are the risks minor issues that can be fixed, or major red flags like poor safety standards or a dishonest management team?

Delivering Feedback to the Supplier

Schedule a formal meeting with the factory management to discuss your audit report. Be professional and constructive. Acknowledge their strengths first, then clearly communicate any areas of non-conformance. For any issues, request a Corrective Action Plan (CAP) with a clear timeline for implementation.

Request A Factory Audit ConsultationWhen to Hire a Third-Party Inspection Service?

While conducting an audit yourself provides the best firsthand knowledge, it's not always feasible. Hiring a reputable third-party inspection service (like SGS, Intertek, or Bureau Veritas) is an excellent choice when you have limited resources, are geographically distant, or require an exceptionally high degree of objectivity and technical expertise. These firms have trained local auditors who can execute a professional assessment on your behalf.

Conclusion: Audit for Confidence, Not Just Compliance

Request A Factory Audit Consultation

A comprehensive factory audit is more than a simple compliance check; it's your most powerful tool for building confidence in a potential supplier. By using a detailed checklist, you empower your business to make informed, data-driven sourcing decisions. View the audit not as a test to be passed or failed, but as the first step in building a transparent, collaborative, and long-lasting partnership that will be the bedrock of your supply chain for years to come.

Request A Factory Audit Consultation

Frequently Asked Questions (FAQs)

Q: How long does a typical towel factory audit take?

A: A thorough audit of a medium-sized towel factory typically takes one full day. This allows enough time for an opening meeting, a complete factory tour, document review, and a closing meeting to discuss initial findings.

Q: What are the biggest red flags during a towel factory audit?

A: Major red flags include unsafe working conditions (blocked fire exits, lack of safety gear), evidence of child or forced labor, extreme disorganization and filth, a refusal to show certain areas of the factory, and an inability to provide basic documentation like a business license or quality certificates.

Q: Can I use this checklist for other textile factory audits?

A: Yes, the core principles and sections (Company Profile, QC, Social Compliance, etc.) are applicable to most textile factory audits. However, you should tailor the 'Production Capability' and 'Testing' sections to the specific product, such as garments or bedding.

Q: What if the factory refuses an audit?

A: A factory's refusal to allow an audit is a significant red flag. A transparent and confident manufacturer should welcome the opportunity to showcase their facility. If they refuse, it's generally advisable to walk away and find another supplier.