The Ultimate Guide to Sourcing Custom Towels from China (2025 Edition)

Published on October 30, 2025

Sourcing custom towels from China presents a massive opportunity for e-commerce brands, hotel chains, and promotional product distributors. The combination of advanced manufacturing, competitive pricing, and vast customization options makes China the undisputed global leader. However, success hinges on a deep, actionable framework. This 2025 guide provides that framework, cutting through the noise to help you find reliable suppliers, negotiate effectively, and import high-quality products that will delight your customers and boost your bottom line.

Section 1: Decoding Towel Quality: Your Foundation for Success

Explain that defining quality before searching for suppliers is the #1 rule. A vague request leads to inaccurate quotes and wasted time. A professional buyer provides a detailed Product Specification Sheet (Tech Pack). This document is your manufacturing blueprint.

Choosing the Right Material

The material is the heart of your towel. Your choice impacts feel, absorbency, durability, and price. Below is a breakdown of common materials.

| Material | Key Characteristics | Best For | Price Point |

|---|---|---|---|

| Standard Cotton | Good absorption, durable | General use, promotional | $$ |

| Combed Cotton | Softer, stronger, less lint | Mid-range bath & hotel | $$$ |

| Pima/Egyptian Cotton | Ultra-soft, highly absorbent, luxury | High-end hotels, luxury retail | $$$$ |

| Microfiber (Polyester/Polyamide) | Fast-drying, lightweight, excellent for printing | Sports, gym, cleaning, beach,car washing | $$ |

| Bamboo | Hypoallergenic, sustainable, very soft | Baby towels, eco-conscious brands | $$$ |

Understanding GSM (Grams per Square Meter)

GSM is the measure of a towel's density and quality. Higher GSM means a heavier, more absorbent, and plusher towel.

- 300-400 GSM: Lightweight (promotional, gym towels). Some styles of Microfiber Towels can be 200gsm, pls contact us for more details

- 400-600 GSM: Medium weight (standard bath, beach towels).

- 600-900 GSM: Heavyweight, luxury (premium bath, spa towels).

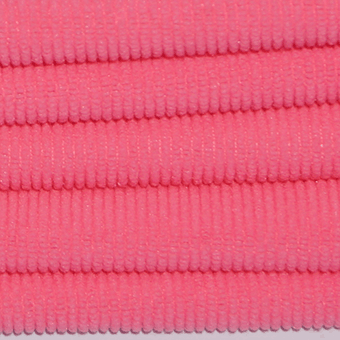

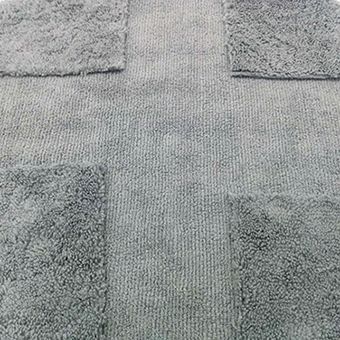

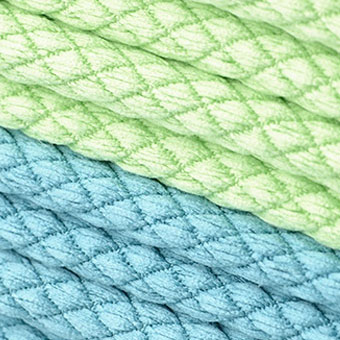

Detailing Weave and Construction

The weave affects the towel's texture and function. Terry cloth is the most common, but other weaves like Waffle, Velour, and Jacquard offer unique properties for specific applications.

Section 2: The 7-Step Sourcing Lifecycle: From Idea to Delivery

This is the core of the article. Following these steps systematically minimizes risk and ensures a smooth process.

- Define Your Product & Create a Tech Pack: Explain what a tech pack is and why it's crucial (specs, colors, size, weight, artwork).

- Supplier Discovery (Beyond Alibaba): Briefly mention Alibaba, Why not suggest alibaba? click here to learn more. but focus on other methods: Canton Fair, sourcing agents, and visiting industrial clusters, google search, AI search.

- RFQ & Initial Vetting: Explain how to write a professional Request for Quotation (RFQ) and how to screen initial responses.

- Sample Evaluation: Detail how to test samples for weight, absorbency, colorfastness, and shrinkage.

- Negotiation & Contract: Provide tips on negotiating price based on volume and payment terms (e.g., 50% down, 50% on before delivery).

- Production & Quality Control: Explain the 3-stage QC process: Pre-Production Sample (PPS) approval, During Production Inspection (DPI), and Final Random Inspection (FRI).

- Logistics & Shipping: Explain EXW, FOB, CFR,CIF and DDP in simple terms, advising buyers to use a freight forwarder for FOB to control costs or CIF to save time.

Section 3: A Regional Guide to China's Towel Manufacturing Hubs

Present this as a strategic way to target the right suppliers. Knowing these regions helps you find the right type of supplier for your specific needs.

- Hebei (Shijiazhuang and Gaoyang): The "Towel Capital." Best for high-volume, cost-effective cotton towels. Ideal for hotels and institutions, Cotton towels,microfiber towels,bamboo towels all produced from Hebei Province, China EverBen Towels Manufacturer located in Shijiazhuang, Hebei. More details of Towels in Hebei, Pls click here.

- Shandong: Strong in both cotton and home textiles, often balancing cost and quality.

- Jiangsu (Nantong, Suzhou): Hub for high-end textiles. Best for premium microfiber, specialized sports towels, and high-GSM luxury cotton.

- Guangdong (Guangzhou, Foshan): Export-oriented, highly flexible with customization, strong in printing and finishing. Great for promotional and retail brands.

Section 4: Vetting Top Suppliers: What to Ask

Do not just list suppliers. Instead, list the critical questions to ask a potential supplier, based on the knowledge from the previous sections. Evasive or negative answers are a major red flag.

Example Questions:

- "Can you provide a copy of your current BSCI and OEKO-TEX certificates?"

- "What is your standard QC process for an order like mine?"

- "What is your lead time for a pre-production sample?"

- "Based on a 1000-unit order of a 600 GSM cotton bath towel, what is your estimated FOB price?"

Section 5: Customization Deep Dive & Quality Control

This is where you bring your brand to life. The ability to customize color, size, shape, jacquard, embroidery, and weight is what makes sourcing from China so powerful. Always verify quality through inspections.

Quality control is not something you do at the end; it's a process you manage from the beginning. "Trust, but verify" is the mantra of successful sourcing. This involves pre-production material checks, during-production inspections, and a final random inspection before shipment.

Section 6: The Ultimate Importer's Checklist

Create a final, actionable checklist in a formatted block. Following this will put you in the top 10% of buyers and set you up for long-term success.

Conclusion

While sourcing from China is complex, a structured, knowledge-based approach minimizes risk and leads to a successful, profitable partnership. The rewards—high-quality products at a fraction of domestic costs—are well worth the effort.